The parking garage across from the house where rapper Jay-Z grew up in New York may not be the site of a revolution that could change the face of farming in the world.

Ten containers occupy one corner of the garage in Brooklyn. Each has climate-controlled technology, and they grow herbs that are distributed to local shops on bicycles. This is the literal meaning of farming in cities or urban residential areas rather than in farms and countryside.

The containers are owned by Square Roots, one of the rapidly expanding vertical farming companies, a sector dominated by a group of tech-savvy entrepreneurs who see food production on the brink of crisis.

The Italian city of Genoa has a global reputation as the best producer of basil. But Square Roots was able to produce Genoa basil in one of the containers, whose climate conditions were adjusted to simulate the city's daylight hours, humidity and carbon dioxide levels, all of which are dissolved in the plant's nutrient water.

Instead of shipping food around the world, we can ship climate conditions and feed them into operating systems," says Tobias Biggs, one of the company's founders.

Skip topics that may interest you and continue reading. Topics that may interest youtopics that may interest you. End

Big Cost

The company was founded by Biggs, an expert in artificial intelligence, two years ago, with investor Kimbal Musk (Elon Musk's brother). They signed an agreement with one of the largest distribution companies, Gordon Food Services, to place the containers in some of their warehouses.

He says that the agreement summarizes everything related to indoor agriculture, as it grows locally, is transported quickly to the market, and its production is fresh and available throughout the year, free of pesticides, and is not affected by weather fluctuations.

Skip the podcast and read onMorahakatyTeenage taboos, hosted by Karima Kawah and edited by Mais Baqi.

The episodes

The end of the podcast

Indoor farming, Biggs added, "provides a lot of answers to the concerns of modern consumers, such as the origin, environmental sustainability, and health benefits of food."

Jeffrey Landau, director of business development at Agriculture Consulting, estimates that the global value of the vertical farming market will increase to about $6.4 billion by 2023, from $403 million in 2013. Half of that increase is due to the United States.

Despite the high cost and the limited number of species that can be grown in this way, investors have not lost hope. Recently, Aero Farms, a producer of lettuce and other leafy greens, secured $100 million in financing from IKEA's owner, Ingka Corporation. Puri Farming also secured $95 million in financing in 2018, backed by Google Ventures and Uber CEO Dara Khosrowshahi, bringing its total investment to $122.5 million.

One of the largest US companies, Plenty, also received funding from SoftBank President Masayoshi Son and former Google Chairman Eric Schmidt. The company aspires to build hundreds of vertical farms in China. And in the UK, food delivery company Ocado is investing in indoor farming technology.

There are other failure stories, however. Landau says, "Vertical farms are very investment and capital intensive. Perhaps the most expensive are lighting systems. Then comes ventilation, air conditioning, irrigation and harvesting."

"A simple mistake can lead to huge repair costs," he added.

Biggs chose a modular system based on shipping containers, which he says makes it easier to quickly control production volumes according to demand. "We can set up an herb farm in a new city for less than $500,000 and it will grow in two months. We just have to press a button for basil, or mint, or tarragon, and the box will adjust the settings to provide the most suitable conditions for the species to grow."

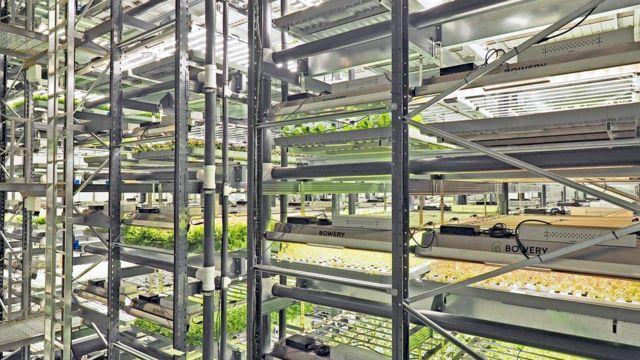

Things are different at Bury Farming, which is located in New Jersey. The five-year-old company operates factory-sized farms. Outside one of its windowless warehouses, a thermostat flashes through the concrete walls. It is a great contrast to the cool atmosphere inside the warehouse, where the smell of fresh crops wafts upon entering.

The robot

The plants grow on stacked planks up to ceiling height, making maximum use of the height. The process is fully automated, from planting machines to harvesting, and is managed by a special operating system that controls lighting, adjusts nutrient levels in the water, and takes pictures of each plant to monitor its health.

"The operating system is the central nervous system," says Irving Fine, founder of the company. "There are a lot of data points. The AI is in a continuous learning process, anticipating how to produce the best possible product."

He added that it is difficult to manage the farm manually, but the workers manage the production process through computer screens and tablets.

Indoor cultivation began decades ago, but the big boost came with the development of LED lights and lighting systems at a lower cost. By combining this technology with robotics, innovations and artificial intelligence, the industry has become - as Fine describes it - dynamic and scalable.

However, the biggest question was how to grow large quantities at the same high level of quality.

Suddenly, the economic calculations changed, "so we can continue to produce for 365 days a year, in a major shift from the usual farming methods for thousands of years. Unlike traditional farming, the quality of our crop can be guaranteed by 100 percent."

The pioneers of vertical farming speak with the accent of entrepreneurs from a tech background. With population growth and climate change, pressures on food production increased, and the owners of these projects became more convinced of their ability to provide solutions.

Here emerges one of the challenges facing this industry, as the world cannot depend on leafy greens for its food. And Fine believes that the ability of the "Buri" company to grow lettuce or cabbage "will continue to be a success in itself." But he aspires to more, as his company produces types of kale, and he expects them to appear on the market in the coming years.

Square Roots also hopes to begin commercial production of beets and strawberries, and is experimenting with seeds it says are rare and forgotten.

Carbon Footprint

It makes sense to grow fresh crops, which cannot withstand shipping for long periods, in the same area of consumption. Crops such as tomatoes and strawberries are grown for transportation, not for taste. It is illogical. To grow vertical planters with the aim of having a longer shelf life.”

But Landau says different types of farming face different challenges. Lighting is not the same for plants. Fruiting and flowering crops, such as tomatoes, strawberries and peppers, have different needs.

Landau continued: "The lighting needed by such crops will be very expensive, require more electricity, and produce more heat, which means more cooling is required. Harvesting these crops will also have a large operating cost."

However, experiments are now being conducted on this technology. In the United States, Oishi produces more than 200 varieties, including 34 edible flowers. Plenty is experimenting with watermelon cultivation. With the decline in the cost of technology, and the increase in research and development, it is expected that the technology will expand to include the production of other types.

This may mitigate criticism of the sector's carbon footprint. Any discussion of the difference between artificial and natural light ends with the latter's preponderance. Proponents of indoor farming then point to the cost of transportation and the waste of traditional farming.

So far, Landau finds concerns about the carbon footprint justified, but he expects indoor farms to shift rapidly to renewable energy.

"Given markets that suffer from harsh weather conditions, or islands that import most of their food, indoor farming can be an important option," he said.

Beggs stresses that this sector is still in its infancy, and he is trying to define optimal work models and directions. Entrepreneurs may not agree on everything, but they all agree that vertical farming has the potential to revolutionize food production globally.